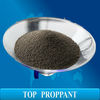

high-strength ceramic proppant 1.Abroad trans 2.Passed ISO & API 3.Tested by Stim-Lab &FracTech 4.Supply Weatherford, Shell

TOP TRADING COMPANY LIMITED

Fracturing Ceramic Proppant

Since established in 1996, we have maintained long-term cooperation with major oil and gas companies at home and abroad for many years. The company has strived for products with high quality but low costs.

Advanced facility &superior products

S Scale: 6 fracturing proppant lines with annual capacity of 210,000 MT

S Facility: advanced sieving system which has independent intellectual property

S Automation: digital automatic control system

S Environment protection: natural gas combustion system

Sound quality control system

S Labs: 1300m2 TOP R&D Center

S Quality testing: raw material, semi-finished product, finished product, stocking and delivery testing

S Samples management: kept for more than 2 years

S Standard: ISO9001-2008 and API

S Authentication: Reservoir Stimulation Laboratory of RIPED-Langfang, Petro China, Stim-Lab and Frac tech Lab

Global network

S Customers: SINOPEC and CNPC

United States, Canada, Russia, Kazakhstan, Ukraine, Brazil, etc.

S Logistics: Deliver to well sites world wide

S Service: Oversea office

Process

1. Milling and Mixing

Milling and mixing processes are controlled by advanced computers and electronic sensors to ensure correct raw material portions, particle sizing and even mixture with automatically.

2. Pelletization

It uses 2 meter and 4 meter diameter rotary granulators with advanced electronics to control spraying pelletization for ensuring proper bead sizing.

3. Drying and Sieving

Rotary dryers using electronic controls to limit the fine dusty particles and maintain proper moisture content of the semi-finished beads.In the sieving process, with the combination rotary sieves that developed by our technicists, separate particle by size through multiple passes with frequent sample and inspection during production.

4. Sintering

Electronic temperature control ensures the product quality in our rotary sintering kilns. To provide a clean work place and reduces the pollution, we use natural gas rather than coal as fuel.

5. Classification

After sintering, the ceramic beads are cooled and sieved then classified into different product sizes.

6. Homogenization

The homogenization lines thoroughly mixes the ceramic beads from each batch to ensure color and quality consistency throughout the batch.

7. Storage

The last procedure is packaged in accordance with contract requirements and stored in indoor warehouses to prevent moisture, dust and damage.

NO.3

API certified fracturing ceramic proppant