Detailed Product Description

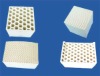

Structured ceramic packing

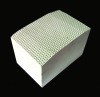

Structured ceramic corrugated board packing

Ceramic packing a large specific surface area, fluxes, resistance to small, high efficiency, resistance to corrosion, high temperature (up to 1000 degrees Celsius above), operating flexibility, amplification effects not obvious advantages. Wider use of chemicals, metallurgy, gas system fluoride and other industries in the drying tower, the absorption tower, cooling towers, and other renewable tower.

Ceramic Structured Packing

Ceramic corrugated packing is composed of many packing units with the same geometric shapes. Each packing unit consists of parallel superposed corrugated sheets. Ceramic structured packing has high efficiency, low pressure drop, high capacity, small liquid holdup; scale effect is not obvious, large flexibility, corrosion resistance, heat resistance etc. It can widely used in the coal gas scrubbing towercoking scrubbing benzene tower,scrubbing NH3 tower,fertilizer saturation-heat water column and scrubbing sulpher tower etc.

Type and Technical Parameter

Type | Thickness | Surface Area | Void Fraction | Bulk Density | TS | Pressure Drop | F Factor |

mm | m2/m3 | % | kg/m3 | m | mm | m/s(kg/m3)1/2 | |

700y(x) | 0.8±0.1 | 700 | 70 | 680 | 6-7 | 5.3 | 1.2-1.3 |

550y(x) | 0.8±0.2 | 550 | 73 | 600 | 5-6 | 4.6 | 1.4-1.8 |

500y(x) | 1±0.2 | 500 | 74 | 590 | 4.5-5 | 5.1 | 1.3-1.5 |

450y(x) | 1±0.2 | 450 | 76 | 552 | 4-5 | 4.4 | 1.5-1.2 |

400y(x) | 1.2±0.2 | 400 | 83 | 530 | 4-4.5 | 2.8 | 1.6 |

350y(x) | 1.2±0.2 | 350 | 80 | 490 | 3.5-4 | 2.6 | 2 |

300y(x) | 1.3±0.2 | 300 | 81 | 470 | 3-3.5 | 2.5 | 2.2 |

250y(x) | 1.4±0.2 | 250 | 82 | 450 | 2-3 | 2.2 | 2.5 |

160y(x) | 2.2±0.2 | 160 | 84 | 384 | 1.5-2 | 1.8 | 2.8 |

125y(x) | 2.5±0.2 | 125 | 85 | 370 | 1-1.5 | 1.5 | 3 |

100y(x) | 2.5±0.2 | 100 | 87.5 | 320 | 1 | 1.3 | 3.5 |