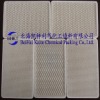

Material: cordierite, mullite, alumina, corundum and corundum mullite. Size: 150x150x300-1200mm. Apply to RTO,RCO,VOC and SCR.

Honeycomb thermal store catalyst ceramic is used for waste gas treatment (RTO,RCO) of the different requirements, selecting many kinds of new highly effective ceramic material to make. It has the following notable characters: large specific surface area, little resistance loss, small heat-expand and cold-contract coefficient, high water-absorbing ratio, good fracture resistance and moderate Millipore aperture.

1. Physical & chemical properties of honeycomb thermal store catalyst ceramic:

| Material

Item | Alumina Ceramic | Loosen Mullite | Compact Cordierite | Loosen Cordierite | Stoneware Porcelain | |

| AL2O3(%) | 52.0 | 68.3 | 25.5 | 35.4 | 30.4 | |

| SiO2(%) | 43.3 | 28.9 | 57.2 | 51.5 | 66.1 | |

| MgO(%) | 0.1 | 0.2 | 7.9 | 11.5 | 0.13 | |

| Other(%) | <3.5 | <2.0 | <3.0 | <1.5 | <3.0 | |

| Material Density | g/m3 | 2.68 | 2.31 | 2.42 | 2.16 | 2.47 |

| Loose Density | Kg/m3 | 965 | 832 | 871 | 778 | 889 |

| Coefficient of Thermal Expansion | ×10-6/°C | 6.2 | 6.2 | 3.5 | 3.4 | 4.8 |

| Specific Capacity | J/Kg K | 992 | 998 | 942 | 1016 | 897 |

| Thermal Conductivity | W/Mk | 2.79 | 2.42 | 1.89 | 1.63 | 1.37 |

| Resistance to Fluctuated Temperature | K | Max 500 | Max 550 | Max 500 | Max 600 | Max 500 |

| Softening Temperature | °C | 1500 | 1580 | 1320 | 1400 | 1380 |

| Highest Working Temperature | °C | 1400 | 1480 | 1200 | 1300 | 1280 |

| Average Thermal Capacity | KWh/m3K | 0.266 | 0.231 | 0.228 | 0.219 | 0.222 |

| Porosity Ratio | % | 0.8 | 26.0 | 0.4 | 15.0 | 0.6 |

| Acid Resistance | % | 0.2 | 2.5 | 5.0 | 16.7 | 0.3 |

2. Specification of honeycomb thermal store catalyst ceramic:

| Outside Dimension | 150×150×300(mm) | ||

| Number of Hole(cells) | 25×25=625 | 40×40=1600 | 50×50=2500 |

| Aperture(mm) | 4.9 | 3.0 | 2.4 |

| Thickness of Inner-wall(mm) | 1.0 | 0.7 | 0.6 |

| Specific Surface Area(m2/m3) | 540 | 825 | 1050 |

| Cell-opening Ratio(%) | 67 | 64 | 63 |

Honeycomb Thermal Store Catalyst Ceramic