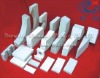

Acid & Heat Resistant Brick for 8 years ISO9001:2008 Special Made To Order

Acid/heat resistant tiles, plates and tubes are special materials used in various reaction kettles, columns, tanks, and stiring pools, saturexes as well as high temperature/cold shock/strong acid resistant liners in non-ferrous metal smelting and chemical industries. Strictly tested by experts from Beijing General Design Institute of Non-ferrous Metallurgy, Gansu Chemical Research Institute, Jingdezhen Ceramic Institute, Ministry of Nuclear Industry [PRC] and South China University of Technology, etc, each technical index of this product meets the international advanced level.

Technical specification| Performance | Heat acid brick/plate /tube | Porous ceramic filter brick / plate / tube |

| Packing density (g/m3) | 2.21-2.24 | 1.48 |

| Porosity () | 9.3-10.5 | 30-43 |

| Water absorption () | 4.2-4.7 | 23.3 |

| Thermal Stability () | 950-20 Three not crack | 200-19 |

| Flexural Strength (MPa) | 2138 | 5.3 |

| The compressive strength (MPa) | 123 | 14.0 |

| Thermal conductivity (W/m.k) | 1.175 | 1.1 |

| Coefficient of thermal expansion (1/) | 3 2×10-6 | 39×1.0-6 |

| Flooding rate (kg/m2·h) | / | 15000 |

| Ventilation rate (Nm3/m2·h) | / | 1.8-5.0 |

| Acid () | 98.7 | 98 |

| Alkaline () | 84 | 74-82 |

| Name | Specification | Name | Specification |

| Standard Brick | 230×113×65 | acidproof porcelain board | 180×110×25 |

| Standard Brick | 230×113×45 | acidproof porcelain board | 150×150×15-50 |

| mold agreement brick | 230×113×65/55 | acidproof porcelain tube | 100×250×10 |

| mold agreement brick | 230×113×65/45 | acidproof porcelain tube | 80×250×8 |

| vertical stroke agrees the brick | 230×113×65/35 | pore tube funne | 50×30×500 |

| vertical stroke agrees the brick | 230×113×65/25 | pore tube funne | 75×30×700 |

| pore to filter the board | 250×250×50 | pore tube funne | 100×60×700 |

| pore to filter the board | 300×300×65 | pore tube funne | 200×140×1000 |

Acid & Heat Resistant Brick