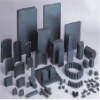

Hard ferrite magnet 1) Low cost 2) High working temperature 3) Good corrosion resistance

Hard ferrite magnets, made by molding powder mixture of about 80% Fe2O3 and about 20% either BaCo3 or SrO3, is also called ceramic magnet. Along with deepening of research, some additives such as cobalt (Co) and lanthanum (La) are mixed together to improve the magnetic performance. The molded powder metallic green is sintered inside a temperature controlled furnace what is heated with electricity or coal. Though hard ferrite magnet is with low magnetic property, it is still a preferable choice to engineer in their design due to several factors: abundantly available raw material,the cheapest cost among permanent magnet family, low density, excellent stability of chemistry, high maximum working temperature and Curie temperature.

Applications of Ceramic Magnets

Speaker magnetsDC brushless motorsMagnetic Resonance Imaging (MRI)Magnetos used on lawnmowers and outboard motorsDC permanent magnet motors (used in cars)Separators (separate ferrous material from non-ferrous)Used in magnetic assemblies designed for lifting, holding, retrieving and separating| Grade | Wb/m2 | Br | KA/m | BHc | KJ/m2 | (BH) max |

| Gs | Oe | MGOe | ||||

| Y25 | 3500-3900 | 0.35-0.39 | 152-208 | 1900-2600 | 22.3-25.5 | 2.8-3.2 |

| Y30 | 3800-4200 | 0.38-0.42 | 160-216 | 2000-2700 | 26.3-29.5 | 3.3-3.7 |

| Y35 | 4000-4400 | 0.40-0.44 | 176-224 | 2200-2800 | 30.3-33.4 | 3.8-4.2 |

| Y15H | ≥3100 | ≥0.31 | 232-248 | 2900-3100 | ≥17.5 | ≥2.2 |

| Y20H | ≥3400 | ≥0.34 | 248-264 | 3100-3300 | ≥21.5 | ≥2.7 |

| Y25BH | 3600-3900 | 0.36-0.39 | 176-216 | 2200-2700 | 23.9-27.1 | 3.0-3.4 |

| Y30BH | 3800-4000 | 0.38-0.40 | 224-240 | 2800-3000 | 27.1-30.3 | 3.4-3.8 |

Ferrite Magnet