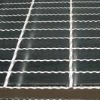

Serrated steel bar grating High strength; Non-skid Excellent rust-proof property Maintenance-free; Aesthetic

Steel grating specification:

| Specifications of steel gratings | ||

| No | Item | Description |

| 1 | Bearing bar | 20x5, 25x3, 25x4, 25x5, 30x3, 30x4, 30x5, 32x3, 32x5, 40x5, 50…75x8mm, etc. |

| 2 | Bearing bar pitch | 25, 30, 30.16, 32.5, 34.3, 40, 50, 60, 62, 65mm, etc. |

| 3 | Cross bar | 5x5, 6x6, 8x8mm (twisted bar or round bar) |

| 4 | Cross bar pitch | 40, 50, 60, 65, 76, 100, 101.6, 120, 130mm or as customers’ requirement. |

| 5 | Surface treatment | Untreated, Hot dip galvanized, Cold dip galvanized, Painted, Powder coated, or as customers’ requirement. |

| 6 | Flat bar type | Plain, Serrated (tooth-like), I bar (I section) |

| 7 | Material standard | Low carbon steel (CN: Q235, US: A36, UK: 43A) |

| 8 | Galvanization standard | CN: GB/T13912, US: ASTM (A123), UK: BS729 |

| 9 | Steel grating standards | A. China: YB/T4001-1998 |

| B. USA: ANSI/NAAMM (MBG 531-88) | ||

| C. UK: BS4592-1987 | ||

| D. Australia: AS1657-1988 | ||

| E: Japan: JJS | ||

Steel grating standards:

A. China: YB/T4001-1998

B. USA: ANSI/NAAMM (MBG 531-88)

C. UK: BS4592-1987

D. Australia: AS1657-1988

E: Japan: JJS

Flooring galvanized Steel Grating is made by Carbon or mild steel of certain sizes through the processing of grooving, cutting, press-welding, and galvalizing. Gratings can be actually made from copper, aluminum and other materials. However, galvanized steel grating is the widely used for its economical cost and excellent properties.

Application:

Steel grating, with exquisite design and robust spanning abilities, is very strong and safe for the floor support and elevated walkway. It can be used for ceiling, interior decoration, decoration, platform aisle, ventilation windows, (Wells), advertising plaque and other construction.

Fields of Application:

Chemical industry, Petro-chemistry, Machinery industry, Textile chemistry, Port engineering, Oil and grease chemistry, Agriculture husbandry, Horticulture, Steel industry, Waste disposal, Food processing, Aquatic breeding, Fertilizer industry, Pharmaceutical industry, Parking lots, Cement plants, Oil refinery, Mining and refinery, Power plants, Public utility, Marine engineering, Shipbuilding, Construction material industry, Defense projects, Airport projects, Water plants, Sewage disposal, Paper and pulp industry, Construction industry, Transportation industry, Automotive industry

Materials:Q235, A36, etc.

Advantages:

Steel grating offers the following advantages compared with steel grid sheets:Steel grating has light weight, good strength, large carrying capacity and can save materials and cost. It has good ventilation of light and wind, a modern sense, aesthetic appearance and anti-skid. It is also easy to clean, easy to installation and durable service time for uses.

Specific application:

Steel grating products are designed and manufactured for various industrial and civil constructions in city road, gardens, yard, airport, railway and industrial engineering, and they offer the following the features:

Features:

Aesthetic outlook: Simple lines and silver appearance meeting the modern trend.

The best drainage: Leakage area of 83.3 percent, more than twice of cast iron products. Hot-dip galvanized treatment: Good rust-proof property, maintenance-free replacement. Anti-theft design: The cover and the frame is joint with hinge offering security, safety and open convenience.

Savings investments: Large-span. Less lost for heavy load compared with cast iron products. Cost can be saved for the risk of being stolen or crushing one if cast iron is uses.

High strength: The strength and the toughness are much higher than cast iron. Can be used for terminals, airport and other large-span and heavy loading condition. Specifications: More specifications and sizes optional for meeting various environment, load, span, sizes and shapes.

Surface Treatment:Untreatment: black

Treatment: hot dip galvanied

Serrated steel bar grating