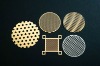

metal disk 1.Low cost for molding or tooling 2.Delivery on time 3.ROHS complaint 4.ISO14001:2004 certificated

Technical Data:

Machining Type | Chemical etching / photo etching, Laser cutting, stamping |

Material Capabilities | Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Aluminum, Alloy (Thickness from 0.03 mm up to 1 mm) |

Product Dimension | 1* 1mm to 550* 550mm. |

Minimum Order Quantity: | Negotiable Trial Order |

Smallest open hole | ØO= 0.1mm when Thickness range from 0.03mm to 0.05mm =1.5*Thickness |

Centre to Centre for holes | =1.5*Thickness |

Smallest line width | 0.05mm. |

Product precision | ± 0.01mm (common difference). It’s generally 20% of material thickness. |

Surface treatment for choice | Planting / Painting, electro-polishing |

metal disk

disk with features other processes would find difficult or impossible to make can be made by the chemical etching process. During the etching process we dissolve any unwanted material allowing us to create intricate features in the form of very fine webs and very small holes.

For the width of the webs in a screen, the general rule in design is webs must be at least 2/3rd the thickness of material. For instance, on a screen etched out of .010 thick material the webs on the screen must be at least .006 wide.

Our process can also make screens that require small holes. The openings on the screen must be at least 20% larger than the material thickness. Therefore on a .010 thick screen the holes must be at least .012 in diameter.

Reel-to-Reel Chemical Etching can creates highly-repeatable unstampable, burr-free components with complex features for intricate metal designs and shapes on a continuous metal strip made from wide variety of ferrous and nonferrous materials.

This process can hold very close tolerances, and extremely high level of repeatability, and true position from metal part to metal part. The degree of precision and consistency achievable offers a continuous chemically etched metal strip and a mass production advantage alternative to the standard panel or sheet etching process.

Specifica of your high precision metal parts

1.Material and thickness(0.001'' to 0.048'' thick)

Alloy 42 Alloy 48 Beryllium Copper BrassCopper Hastalloy Hy-mu 80 InconelInvar Kovar Metglas MolybdenumMuMetal Permalloy 80 Phosphor bronzeSilicon steel Spring steel Steel Stainless Steel 2.Tolerance we can achievethickness below 0.2 mm, tolerance can be controled in +/-0.015mmthickness below 0.5 mm, toleracne canbecontroled in+/-0.05 mm 3. Largest dimension of the parts we can make is 700mm * 700mm, smallest hole diameter is 0.1mm, it will be different when the thickness is different, but generally, hole diameter is 1.5 times of the material thickness. Main market and customers

chemical etching encoder disk export