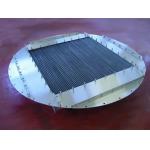

Mist eliminators made of knitted wire mesh forms primary parts for the mist collection systems. Zhengyang offers a full line of mist collectors including continuous duty centrifugals. Mist eliminators /collectors are used to collect light mist and swarf. A number of design layouts and filter choices are provided for both flexibility and expandability. Mist eliminators consist of pad sets, or a variety of pleated panel designs. The filter media is normally knitted wire mesh made of metal or synthetic fiber What is a Mist Eliminator? Mist Eliminator, also known as demisters, are essential in many process operations for the removal of entrained material in vapour flows. Mist Eliminators pads provide a wide range of solutions suitable for any application. Operation of a Mist Eliminator is based on having a large number of obstacles intercepting entrained droplets in a vapour flow. This large number of obstacles must provide minimum drop in pressure over the removal system. Mist Eliminator pads are fabricated from knitted materials with interlocking asymmetrical loops of metal or plastic with typical diameters being 0.1 – 0.3mm. By careful choice of wire diameter, DA have produced demisters with extremely high free volumes (typically 98 – 99%) along with very high removal efficiency and low pressure drop. How a Mist Eliminator Works: Elimination of DA Mist Eliminator is dependent on droplet size: 5 – 9 micron 99% >10 micron 99.5% Most of the weight of entrained mist tends to be associated with the larger mist particles (larger than 5 - 10μm) thus providing greater that 99.99% weight removal. Stock Materials commonly used: Stainless Steel: Grades 302, 304, 316, 316L, 321, 309, 310S Super Alloys: Inconel 601, Incoloy DS, Hastaloy, Carpenter 20 Fibrous Filament: 'E' Glass, 'S' Glass, 'A' Glass, Basalt, Ceramic, Silica, Kevlar Others: Aluminium, Monel, Copper, and Brass, Mild Steel (plain and galvanised), Polypropylene, Polyethylene Why use DemisterASIA Mist Eliminators: Our products are known among our customers for good durability. We have also a good track record for having negligible annual production errors for the past few years*. With DA good experience, you can be sure to get the best quality and durability for your DA Mist Eliminators.