cost-saving, high quality and automatic/Simple structure, low operating cost, stable product quality, simple craft, inexpensive

1. Brief introduction

Natural gypsum generally includes dihydrate gypsum and anhydrous gypsum. In order to get the valuable materials, generally, we get semi-hydrated gypsum through heating the dihydrate gypsum.

2. Production scale

20000tons per year ~200000tons per year

3. Main technology

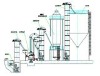

Gypsum mine→ first breaking →second breaking →grinding →calcining →aging →finished products (CaSO4·1/2H2O)

4. Raw materials

Content of CaSO4·2H2O in gypsum mine >80%.

The grade of mine and the crystal configuration will influence the quality of semi-hydrated gypsum.

5. Calcining Technology:

A: rotary kiln

B: fluidized furnace

6. The list of the equipment

No. | Name |

1 | Apron feeder |

2 | Single-rotor Impact crusher |

3 | Screw conveyor |

4 | Circumgyrating, blowing in reverse, pocket dust catcher |

5 | Bucket elevator |

6 | Screw conveyor |

7 | Screw conveyor |

8 | Materials bin |

9 | Single screw brake |

10 | Electromagnetic Vibratory feeder |

11 | Screw conveyor |

12 | Bucket elevator |

13 | Bin before mill |

14 | Electromagnetic Vibratory feeder |

15 | Grinder |

16 | Rotor type separator |

17 | Bucket elevator |

18 | Air blower |

19 | Bucket elevator |

20 | Materials bin |

21 | Speed adjusting screw conveyor |

22 | Bucket elevator |

23 | Bin before furnace |

24 | Speed adjusting screw conveyor |

25 | Roots blower |

26 | Furnace |

27 | High voltage centrifugal air blower |

28 | Whirlwind dust catcher |

29 | High-temperature bag dust catcher |

30 | Flume |

31 | Air blower |

32 | Bag dust catcher |

33 | Bucket elevator |

34 | Grog bin |

gypsum powder production line