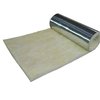

1.Grade A1 non-combustible 2.Acidity coefficient is above 1.8 3.Thermal conductivity(Room temp.) is less than 0.04w/m.k

Rock wool is made from natural rock such as basalt, diabase and dolomite. The natural rock are melted into melts in cupola at a very high temperature about 1500°C. And the melts lava is then pour to high speed spinners through which the melts get into fibers. At the same time, the phenolic binder containing silicon and mineral oil etc are sprayed onto the surface of each fiber homogeneously. The just fiberized fibers are collected together to form the original wool mat through negative pressure resulted from suction. The original wool mats then pass through pendulum, crimping and pressing process, get into the curing oven through which the wool mats are cured and shape up to different kinds of products such as board, mat and pipe section etc with different usage.

Jesion rock wool products are free of asbestos, and do not apply any composition harmful to environments such as CFCs, HFCs and HCFCs etc, no harm to human health, do not increase the risk of cancerogenesis. After many years research, the World Health Organization agency of Research made a decision to exempt rock wool from the list of "possibly cancer causing agents". This decision supported the fact that rock wool is safe to users or worker occupational exposure to rock wool fibers. The properties of non-combustibility, high temperature resistance and porous fiber construction of Jesion rock wool products, makes them have very good performance on fire resistance, thermal insulation and acoustic insulation. The rock wool products are widely use for industry field, building and marine & offshore field to increase the energy efficiency, decrease pollution agent discharge, and improve fire safe situation. Meanwhile, some rock wool products can also be used as the planting substrate for many kinds of vegetables, flowers and fruits. Jesion Exterior Wall Insulation Board(EWB series) is designed for using as insulation materials inETICS. The high compression strength and tensile strength of EWB, together with its low water and moisture absorption, lasting dimension stability against temperature variations, moisture and aging, make it versatility andcompatibility with various external wall insulation systems, and keep its ever lasting thermal, acoustic and fire insulation properties. The reaction to fire is Class A1.Production Process Diagram:

Rock Wool Application for Building:

2013 hot sale wood fiber insulation