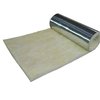

1.Thin and long inner fiber 2.Low thermal conductivity 3.Nice sound-absorbing performance 4.Water-proof Since its thin and long inner fiber, glass wool has good performance in thermal insulation and sound-absorbing. Its thermal conductivity is low. And it can effectively stop air flowing and quickly reduce the transportation of sound. Type:For glass wool, there are two types. One is glass wool board and another is glass wool blanket. Application:It is the best material used for the insulation and sound absorption of steel structures. It is widely used in industrial plant, public facility,warehouse, exhibition centre's, shopping mall, cold store and a variety of indoor playground, sports ground and other buildings. Meanwhile, it can save energy, absorb sounds and improve the indoor air quality in much degree. Despite of glass wool/fiberglass production has been a recognized technology for quite a while now, framing materials using this product are finding enhanced market recognition, due to heightened global emphasis on “green” applications of such products and technologies. Fiberglass has been the material of choice in several applications, including commercial and residential construction for both new and retrofit applications, which offer strength, longevity, durability and thermal efficiency. Though initiation of new construction activities would continue to be sluggish in the developed economies of North America and Europe, glass wool demand in North America is expected to pick up pace due a relatively faster recovery and in the European Union because of the imposition of new building energy efficiency directives for cutting down on CO2 emissions. In EU countries, such as Germany and France, building renovation activities are being undertaken at a frenetic pace, with strong backing from governmental programs with an aim to cut down on energy consumption by buildings. Demand for insulation remains high in regions, such as China, India and Russia because of the burgeoning construction activities and new regulation standards for sustainable buildings being put in place. Asia-Pacific, backed by booming China and other developing countries, has performed well in all sectors that utilize glass wool insulation, with CAGRs ranging from 6 to 8% during 2006-2011, a trend likely to continue over 2012-2016 with high CAGRs between 6.2% and 6.7%. Market for Glass Wool (or Fiberglass) products analyzed for the end-use application areas includes Residential Construction, Commercial & Industrial Construction, Industrial & HVAC Applications and Appliances & Other. Global market for glass wool is projected to reach 6.4 million valued at US$14.1 billion) metric tons by 2016 from an estimated 5.1 million metric tons in 2012, growing by a CAGR of 5.9% between 2012 and 2016. Gass wool technical data:

| Item | Unit | Index | Standard |

| Density | kg/m3 | 10-80 | GB/T 5480.3 |

| Average fiber diameter | um | 5-8 | GB/T 5480.4 |

| Water content | % | ≤1 | GB/T 16400-2003 |

| Grade of combustibility | / | Non-combustible Grade A | GB8624-1997 |

| Reshrinking temperature | °C | 250-400 | GB/T 11835-2007 |

| Thermal conductivity | w/m.k | 0.034-0.07 | GB/T 10294 |

| Hydrophobicity | % | ≥98 | GB/T 10299 |

| Moisture rate | % | ≤5 | GB/T 5480.7 |

| Sound-absorbing coefficient | / | 1.03 product reverberation method 24kg/m32000Hz | GBJ47-83 |

| Slag inclusion content | % | ≤0.3 | GB/T 5480.5 |

| Jesion Glass wool Specification | ||||

| Item | Width(Diameter--MM) | Thickness(MM) | Length(MM) | Density(KG/M3) |

| Board | 600-1200 | 20-100 | 1200-2400 | 24-96 |

| Blanket | 1200 | 25-150 | 11000, 20000 | 12,16, 20, 24, 32, 40, 48 |

| Batt | 410-610 | 100-200 | 1160-1200 | 10-48 |

Package:

Jesion grade A pipe insulation cladding