It is characterized by high porosity,stability and excellent resistance to thermal attack and corrosion from molten steel liquid

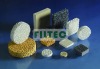

FILTEC® CF200 Ceramic Foam Filter is a phosphate-free, high alumina-based product, It is characterized by high porosity and mechanochemical stability and excellent resistance to thermal shock and corrosion from molten aluminum, It can effectively remove inclusions, reduce trapped gas and provide laminar flow when molten aluminum filtrated, it is machined to tight dimensional tolerance during production, this combination of physical properties and precise tolerance make them first choice for molten non-ferrous filtration. FILTEC® CF200 Ceramic Foam Filters are widely used for molten aluminum filtration in primary and secondary aluminum foundries, they are also applied as media in gas-liquid and liquid-solid separation engineering.FILTEC® CF200 Ceramic Foam Filter is supplied with soft/hard gasket to prevent metal bypass, it is available in dimension of 40-600mm with pore size from 10-40ppi. Special size is also available on order.

FILTEC® CF400 Ceramic Foam Filter is a silicon carbide-based product, it is made by unique technology at FILTEC's ISO-9001 certified plant. It is characterized by high porosity and mechanochemical stability and excellent resistance to thermal attack and corrosion from molten iron liquid, It can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow when applied as filter in gating system. They are machined to tight dimensional tolerance during production, this combination of physical properties and precise tolerance make them first choice for both grey and ductile iron casting. FILTEC® CF400 Ceramic Foam Filters are widely used for molten iron and its alloys filtration in ferrous foundries, they are also applied as gas and dust absorbing media in air-cleaning engineering.

FILTEC® CF600 Ceramic Foam Filter is a Ca/Mg-stabilized zirconia product, it is made by imported raw materials and unique technology. FILTEC® CF600 ceramic foam filters are characterized by high porosity and mechanochemical stability and excellent resistance to thermal attack and corrosion from molten steel liquid, they can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow when applied as filter in gating system. They are machined to tight dimensional tolerance during production, this combination of physical properties and tolerance make them first choice for all types steel foundries.

FILTEC® CF600 Ceramic Foam Filters are widely used for molten steel and its alloys filtration in steel foundries, they are also applied as fuel distributor in burner assembly and absorbing media in high-temperature waste-gas decontamination engineering.

Ceramic Filter (foundry filter)