Usefulness of this stool. And we have our own factory, so we have to guarantee the quality and price concessions

Xiamen Tongchengjianhui Industry & Trade Ltd. is specialized in OEM fitting and machining parts for many years. We have 8 professional engineers and more than 55 experienced staff at your service. Our products mainly used in auto parts and mechanical function.

We have compelete QC system and adopt effective 6s management. Meanwhile kinds of testing machine are available for your reference. So just show us your drawing/sample/idea, we can do one stop service for you, from tooling, casting to machining, polishing and others. We are willing to be your honest partner in China.

The ultimate success of the casting design depends on the communication between the designer and foundry engineers. When the foundry is properly informed of part requirements, there is usually a compromise of specifications that will allow for maximum compliance to print specifications and finish part design.1 Standard Linear Tolerance(mm)As-cast tolerances of angles is mainly a function of the part design and their ocation in casting. They range from +/- 1/2 degree (considered minimum) for well supported positions to +/- 2 degree where existing distortion could be expected. Inclusion of gussets and ribs normally minimizes distortion and many sections can be mechanically straightened.3 Flatness, Strengteness and Roundness

| Section Thickness | Possible Thickness Section Sink per Face of Casting | |

Normal | Premium | |

Up to 25 | 0.20 | 0.10 |

25 to 50 | 0.40 | 0.20 |

50 to 100 | 0.60 | 0.30 |

100 to 150 | 0.80 | 0.40 |

Straightening adds cost, but sometimes cannot be avoided. The actual straightening costs are often dependent on the tightness of the tolerance specified, so do not specify tighter flatness, straightness, roundness, or other requirements than you actually require. (tcjh typically straightens parts using die sets that will be included in your tooling price.)4 Size and Weight Range Size and Weight. Part size and weight are the most critical factors in determining part cost because mold capacity is limited by both size and weight. The more pieces that can run on a mold, the lower the part cost. Unnecessary mass should always be removed by correct engineering practices to reduce part weight.

| Items | Size | Premium |

Outline Dimention | 1000×620×380 | up to 100 |

Weight(kgs) | 0.001-60 | 0.10 to 1.50 |

Min. Wall Thickness | 0.50 | 5 to 10 |

5 Surface Roughness 80 to 120 RMS are average.6 Hole LengthMaking a good hole in a casting is dependent on the integrity of the shell. The ratio of holediameter to length is important in determining what can be offered. Blind holes must have aradius at the top and the bottom of the hole to insure that a strong core is built for castingpurposes and to insure the best possible casting.

7.When possible, parts should be designed so that a single gate can feed the part. This will generally yield more pieces per mold and reduce the pour weight per mold.We build gate grind fixtures for virtually all parts produced that require gate grind. When possible, the part should be designed so the gate can be put on flat surface rather than curved surface. Gate grind tolerances are listed from least to greatest cost.1. Break-off witness (same alloys)2. 0.20-0.50mm high witness3. Flush grind8 Heat TreatmentHeat treatments are used to control hardness, mechanical properties, corrosion resistance, and surface treatments. Unless otherwise indicated, all alloy steels are quoted with a normalize or anneal. All 300 series stainless steels and 17-4PH are quoted with a solution anneal.9 GagingWe perform a 100% visual inspection, However, if dimensional verification is required, a sampling plan and process control is less expensive than 100% gaging of each part. Fixed gages such as "go-no-go" are less expensive to use than gages with dial indicators. (Important: Whenever custom gages are used, there should be identical gages at tcjh and at the customer's plant.)10 Non-destructive TestingAll sample investment castings are non-destructively tested in order to establish first article quality. However, this is generally not required on production commercial investment castings; doing so will add costs. The following non-destructive tests are listed from least to greatest cost:1. Magnetic Particle2. Fluid Penetrant3. X-Ray11 CertificationChemical Certification can be provided at no extra cost. Mechanical Property Certification adds to cost, so it's best to consider a combination of Chemistry and Hardness Certification instead. Marking each casting with heat number also adds to the cost. Investment fitting in lot numbers may be a good tracability option for commercial parts.12 Tooling & CavitiesIf the design contains features that will raise scrap or rework rates (and the piece price), the tcjh Estimating Engineer will recommend design modifications to keep the piece price down.More cavities means higher tooling cost, but lower piece price. Configurations that do not allow metal cores to be drawn must be treated in one of the following ways:1. Collapsible Cores – Lowest piece price, higher tooling cost.2. Loose inserts – Best for low volume parts.3. Multipiece Wax Assemblies – Best for certain configurations, but tolerance control suffers.4. Soluble Cores – Requires additional die and labor.5. Pre-Formed Ceramic Cores – High cost for specialized shapes.13 Alloy GradeAlloys are listed from least to greatest cost:1. Carbon and Low Alloy Steels8620, 4140, 1020, 1035are best choices2. 17-4PH and 400 Series Stainless Steel17-4PH & CA-15 (410) are most frequently pouredDo not specify 416 unless necessary for machinability3. 300 Series Stainless SteelCF-8 (304), CF-8M (316) are best choicesDo not specify CF-16F (303) unless necessary for machinability4. Tool SteelsCosts vary widely depending on grade5. Nickel Base AlloysAlloy C and X are best choices6. Cobalt Base AlloysAll grades pour well – Choice is based on end use and cost7 Heat resistant steelSCH13,SCH22,SCH24,IN519,NW-22,NA22H

You can get from us:

1.High quality Guarantee. We have strict quality control system from raw material, in production and after production. When the goods are ready, we also have 15% spot check. Distinguished customer inspection are also warmly welcomed.

2.Competitive price. We are ISO9001:2000 factory and have our own purchase department and cost control department. Producing so many years machining parts, we also have a good reputation and relationship with material supplier.

3.Technician support. Drawing updated,such as: find the best way to antirust or how to make parts assembly better, etc.

4.Friendship and Long-term cooperation. You will be our great friends through our cooperation. All of our staff willing to make friends with you. Also you will find your other suppliers by our efforts.

OEM aluminium die casting parts made strictly according to your specified drawings or samples, with good quality and low price.

Aluminum die Castings

1) OEM aluminium die casting parts made strictly according to your specified drawings or samples, with guaranteed quality and reasonable price;2) A happy one-stop procurement experience, because we do not only supply die-casting and machining service by ourselves, but also outsource surface treatment services form nearby factories, such as powder coating, anodizing, electroplating, mirror polishing etc;3) A safe and stable backup. We recognize the importance of customers, wo also knew that our customers also have their customers, so your customers will be satisfied with you because we will make you satisfied.

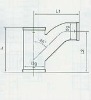

OEM aluminium die fitting parts made strictly according to your specified drawings or samples, with good quality and low price.

fitting1) OEM aluminium die fitting parts made strictly according to your specified drawings or samples, with guaranteed quality and reasonable price;2) A happy one-stop procurement experience, because we do not only supply die-casting and machining service by ourselves, but also outsource surface treatment services form nearby factories, such as powder coating, anodizing, electroplating, mirror polishing etc;3) A safe and stable backup. We recognize the importance of customers, wo also knew that our customers also have their customers, so your customers will be satisfied with you because we will make you satisfied.

Welcome any inquiry from you.

Our material through strict supervision and inspection, the product through layers of processing, stable performance, testing segment " first before detection, processing of random testing, late products ex-factory testing. These are our quality premise. Because we have our own factories in order to avoid multiple profit so the price we offer are lower than others.

Precision Casting quality zinc plated sheet metal bathtub parts and fittings