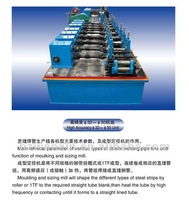

ERW pipe mill is to produce API, EN,ASTM,GB/T etc pipe to transport water, gas and oil, also can produce construction pipe.

Pipe Diameter: 219--610 mm Thickness: 4.0--20mm

Forming speed: 8--20m/min Coil weight: 30 MT

Installed capacity: 5000 KW

The High frequency straight seam welded pipe mill is used to level the fixed strip after slitting line, and entry it to forming machine, bend to pipe by roller, melt the strip edges through the High frequency current, squeeze and weld the pipe by the squeeze roll. The high frequency pipe mill is also called ERW pipe mill.

Technical Process:

Loading coil----uncoiler----leveling----shearing and butt welding----accumulator----forming----HF welding----Intermediate annealing----air cooling---- water cooling----sizing----cutting by fixed length----end facing and chamfering----hydraulic testing----UT testing----marking----storing

ERW pipe making machine (WXZF-610)