1) Long afterglow time:10~12 hours; 2) FREE SAMPLE is available; 3) PAYPAL is available; 4) 11 years' trading experience.

Item Name:photoluminescent masterbatchPlace of Origin:ChinaBrand Name:ChenghaoModel Number:ABS-G-AMOQ: 10kgSupply Ability: 100,000kg/Month Loading Port:QingdaoPayment Terms: T/T, L/C, Western Union, Paypal

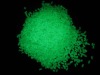

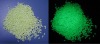

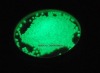

Property:1)Appearance range: Light yellow, light green, light red, light white, light blue,etc.2)Glowing color range: Yellow-Green, Blue-Green, Sky-Blue, Red, Blue, Green,etc.3)Material: rezin(PP, PS, AS, PVC, PE, ABS......) and photoluminescent pigment,etc

Feature:1)Short Storing-light time:10-20 min;2)Long afterglow time: 8~12 hours;3)High luminance4)Wide excitation wavelength:200-450nm,e.g. visible light, Lamp light,UV light;4)Photoluminescent Pigment Recycle time:More than 10 years;5)Safty:non-toxic/non-radioactive/nonexplosive/incombustibly/pro-environment

Use: Can be can be used in different process such as injection molding, extrusion, pouring,

calendering, banbury and so on.

Application:Widely used in plastic products, such as plastic toys, plates, tapes and switches..

Confection of pellets:

Transparent resin 40--60PL pigment 5-50White oil LittleLubricant assistant 5-10Dispersent 1-2

Note: The transparent resin can be PP, PS, AS, PVC or transparent PE, or sometimes can be

opaque ABS.Mix the above-mentioned material evenly, put it into the extrusive machine to be processed

under the normal temperature. When cooled down, cut it into pellets.

Suggest:1> Use the glabrous machine, reduce the friction, decrease damage to machine and lessen the

contamination to PL pigments.2> Because the size of PL pigment particle is big, we can produce the pellets using screw

machine without filtering screen.3> The effect of luminous plastic material will be well if made of luminous masterbatch. And the

ration of the Photoluminescent pigment in the plastic material is between 1~10%. You can

adjust the ratio of luminous masterbatch and white material according to different brightness

request. Usually the ideal Photoluminescent pigment ratio is 4—5%.4> Injection products can be made in one time, just stick the PL pigment evenly to the surface

of pellets.5> You can manufacture plastic plates, chips, tubes and threats by PL plastic pellets.

Specification:

Item No. Glow Color Main Material ABS-G-A ABS&Glow Powder Yellow-greenABS-G-B ABS&Glow Powder Yellow-greenABS-G-C ABS&Glow Powder Yellow-green PP-G-A PP&Glow Powder Yellow-greenPP-G-B PP&Glow Powder Yellow-greenPP-G-C PP&Glow Powder Yellow-green PE-G-A PE&Glow Powder Yellow-greenPE-G-B PE&Glow Powder Yellow-greenPE-G-C PE&Glow Powder Yellow-green PMMA-G-B PMMA&Glow Powder Yellow-greenPMMA-G-C PMMA&Glow Powder Yellow-green AS-G-B AS&Glow Powder Yellow-greenAS-G-C AS&Glow Powder Yellow-green PS-G-A ABS&Glow Powder Yellow-greenPS-G-B PS&Glow Powder Yellow-greenPS-G-C PS&Glow Powder Yellow-green PC-G-B PC&Glow Powder Yellow-greenPC-G-C PC&Glow Powder Yellow-green Nylon-G-B Nylon&Glow Powder Yellow-greenNylon-G-C Nylon&Glow Powder Yellow-green K-resin-G-B K-resin&Glow Powder Yellow-greenK-resin-G-C K-resin&Glow Powder Yellow-green

Packing and Storage1. Packing: 1kg/Plastic Bag inside & Outer Carton; 25kgs/woven bag or customerization.2. Storage: Keep in warehouse where is ventilated, dry and cool with temperature between 15

and30 Degree, relative humidity between 40% and 60%.

plastic masterbatch