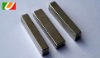

magnetic material N35-N52(M, H, SH, UH, EH) Max temperature: 80-230 degree Shape: tile, block, ring, ball and so on

magnetic material

1.Material: Sintered Neodymium-iron-boron

2.Products manufactured according to ISO9001 quality system

3. Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology

4. The strong permanent magnet

5. High coercive force, the max operating up to 200 degree centigrade or 380 curie temperature

6. High quality with competitive prices

7. The grade: N35-N52(M, H, SH, UH, EH)

8. Various shapes and sizes or according to customers request

9.Various coating to protect magnets such as Ni, Zn, gold copper, epoxy, chemical, and so on

10Widely used in different applications, such as sensors, motors, rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters, automobiles and so on

11. We could provide you the customized magnets according to your request, the prices could bargained

| Grade | Br mT(KG) | bHc KA/m(KOe) | lHc KA/m(KOe) | (BH)max KJ/M3 (MGOe) | Max Working tempt.Tw °C |

| N35 | 1170-1210(11.7-12.1) | ≥868(≥10.9) | ≥955(≥12) | 263-287(33-36) | 80 |

| N38 | 1210-1250(12.1-12.5) | ≥899(≥11.3) | ≥955(≥12) | 287-310(36-39) | 80 |

| N40 | 1250-1280(12.5-12.8) | ≥923(≥11.3) | ≥955(≥12) | 302-326(38-41) | 80 |

| N42 | 1280-1320(12.8-13.2) | ≥899(≥11.3) | ≥955(≥12) | 318-342(40-43) | 80 |

| N45 | 1320-1380(13.2-13.8) | ≥876(≥11.0) | ≥955(≥12) | 342-366(43-46) | 80 |

| N48 | 1380-1420(13.8-14.2) | ≥836(≥10.5) | ≥955(≥12) | 366-390(46-49) | 80 |

| N50 | 1420-1450(14.2-14.5) | ≥860(≥10.8) | ≥955(≥12) | 382-406(48-51) | 80 |

| 35M | 1170-1210(11.7-12.1) | ≥868(≥10.9) | ≥1114(≥14) | 263-287(33-36) | 100 |

| 38M | 1210-1250(12.1-12.5) | ≥899(≥11.3) | ≥1114(≥14) | 287-310(36-39) | 100 |

| 40M | 1250-1280(12.5-12.8) | ≥923(≥11.6) | ≥1114(≥14) | 302-326(38-41) | 100 |

| 42M | 1280-1320(12.8-13.2) | ≥955(≥12.0) | ≥1114(≥14) | 318-342(40-43) | 100 |

| 45M | 1320-1380(13.2-13.8) | ≥995(≥12.5) | ≥1114(≥14) | 342-366(43-46) | 100 |

| 48M | 1360-1430(13.6-14.3) | ≥1027(≥12.9) | ≥1114(≥14) | 350-390(44-49) | 100 |

| 30H | 1080-1130(10.8-11.3) | ≥796(≥10.0) | ≥1353(≥17) | 223-247 (28-31) | 120 |

| 33H | 1130-1170(11.3-11.7) | ≥836(≥10.5) | ≥1353(≥17) | 247-271(31-34) | 120 |

| 35H | 1170-1210(11.7-12.1) | ≥868(≥10.9) | ≥1353(≥17) | 263-287(33-36) | 120 |

| 38H | 1210-1250(12.1-12.5) | ≥899(≥11.3) | ≥1353(≥17) | 287-310(36-39) | 120 |

| 40H | 1240-1280(12.4-12.8) | ≥923(≥11.6) | ≥1353(≥17) | 302-326(38-41) | 120 |

| 42H | 1280-1320(12.8-13.2) | ≥955(≥12.0) | ≥1353(≥17) | 318-342(40-43) | 120 |

| 45H | 1320-1360(13.2-13.6) | ≥1000(≥12.5) | ≥1360(≥17) | 344-376(43-47) | 120 |

| 30SH | 1080-1130(10.8-11.3) | ≥804(≥10.1) | ≥1592(≥20) | 223-247 (28-31) | 150 |

| 33SH | 1130-1170(11.3-11.7) | ≥844(≥10.6) | ≥1592(≥20) | 247-271(31-34) | 150 |

| 35SH | 1170-1210(11.7-12.1) | ≥876(≥11.0) | ≥1592(≥20) | 263-287(33-36) | 150 |

| 38SH | 1210-1250(12.1-12.5) | ≥907(≥11.4) | ≥1592(≥20) | 287-310(36-39) | 150 |

| 40SH | 1240-1280(12.4-12.8) | ≥939(≥11.8) | ≥1592(≥20) | 302-326(38-41) | 150 |

| 42SH | 1280-1320(12.8-13.2) | ≥995(≥12.5) | ≥1592(≥20) | 318-342(40-43) | 150 |

| 28UH | 1020-1080(10.2-10.8) | ≥764(≥9.6) | ≥1990(≥25) | 207-231(26-29) | 180 |

| 30UH | 1080-1130(10.8-11.3) | ≥812(≥10.2) | ≥1990(≥25) | 223-247(28-31) | 180 |

| 33UH | 1130-1170(11.3-11.7) | ≥852(≥10.7) | ≥1990(≥25) | 247-271(31-34) | 180 |

| 35UH | 1170-1220(11.7-12.2) | ≥860(≥10.8) | ≥1990(≥25) | 263-287(33-36) | 180 |

| 28EH | 1040-1090(10.4-10.9) | ≥780(≥9.8) | ≥2388(≥30) | 207-231(26-29) | 200 |

| 30EH | 1080-1130(10.8-11.3) | ≥812(≥10.2) | ≥2388(≥30) | 223-247(28-31) | 200 |

| 33EH | 1130-1170(11.3-11.7) | ≥812(≥10.2) | ≥2388(≥30) | 247-271(31-34) | 200 |

magnetic material