1.Flying Shear 2.OEM 3.small power consumption 4.Longer life expectancy 5. High yield

Rolling steel circular blade shearing machine rolling plate shearing machine called "Rolling Shear" or "flying shear".Because of the shear plate,Arc on the blade along the line of the blade for vertical reciprocating and rolling around thecompound,And the blade under the blade along the approximate line for rolling.Rolling Shear is a complex structure,technical difficulty,a high level of automation,and the support of more than shear auxiliary equipment.The Rolling Shear shear plate wiht high-quality,small power consumption,longer life expectancy and high yield characteristics,so it is a plate shear equipment direction of development.

| Steel Plate Thickness 650mm | |||||||

| Steel Plate Width 1500-3700mm | |||||||

| Steel Plate Length(Max) 42000mm | |||||||

| Cut to Length of the plate length 3000-12000mm | |||||||

| Tailing End Length 100-400mm | |||||||

| Cropping Length 20-400mm | |||||||

| Plate weight 19t(Max) | |||||||

| Plate Temperature ≤150°C | |||||||

| Maximum tensile strength at cold State: | 1200N/SQ M(plate thickness 40mm) | ||||||

| 750N/SQ M(plate thickness 50mm) | |||||||

| Max Shearing Force 15500Kn | |||||||

| Number of time for load shearing 10-12times/min | |||||||

| Gap between Shearing edges ≥200mm | |||||||

| Plate Feeding Speed 0-±2.0m/s | |||||||

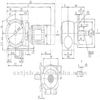

Flying Shear