Spiral Classifier(classifier mill) 1.High classifier efficiency 2.Simple and reliable sturcture 3High classifier productivity

Spiral Classifier/Classifier Mill/Screw Classifier Introduction

Classifier is widely used in shunt ore in the concentrator and ball mill, or grading ores and fine mud in gravity concentrator, or particle size classification in metal beneficiation process, and so on.

This classifier has the feature of simple and reliable structure, easy to operate and so on.

Spiral classifier is divided into: single spiral classifier and double spiral classifier.

According to the different degree of the spiral blade submerged spillway, the spiral classifier can be made into the following two kinds:

1.High weir spiral classifier: Top of the overflow terminal helical vane is higher than the overflow spillway, and overflow spiral center is lower than the overflow spillway. And the high weir spiral classifier is mainly used for overflow particle ore grading that size is 0.83-0.15mm.

2.Submerged spiral classifier: Spiral blade of the overflow is all submerged below spillway. And the submerged spiral classifier is mainly used for overflow particle ore grading that size is 0.15-0.07mm.

Spiral Classifier/Classifier Mill/Screw Classifier Function Characteristics

This machine is high weir spiral classifier, widely used in size grading of pulp in metal beneficiation process, and it can also be used in de-sludge and dehydration in tin ore operation.

The high weir spiral classifier composes of closed-process with ball mill to obtain the overflow products that the size is larger than 0.15mm.

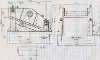

This high weir spiral classifier usually consists of the following components: semicircular flume, transmission device, lifting device, spiral parts and lower bearing.

Spiral Classifier/Classifier Mill/Screw Classifier Working Principle

When it works, it will send the fine grinding pulp from the inlet into the sink. The bottom of the tilt installation sink is the pulp classification subsidence area. Then it will reduce speed rotation and mix the pulp. Thus it can make most clear particles floating on the above, overflow from the overflow edge, and to the next beneficiation process. Coarse particles settle at the bottom, become ore. Then it will be sent to the throat by screw through the chute and enter into the ball mill. At last , it will form a closed system with the ball mill.

Spiral Classifier/Classifier Mill/Screw Classifier Technical Parameter

Specification Model | Flume Slop | Equipped Power(kw) | Production capacity(t/d) | Machine Weight(t) | |

Sand Return | overfall | ||||

300 | 12 | Y1.1-6 | 30-80 | 10_30 | 1 |

500 | 14-18 | Y1.1-6 | 140-260 | 32 | 1.6 |

750 | 14-18 | Y3-6 | 250-750 | 65-174 | 2.7 |

1000 | 14-18 | Y5.5-6 | 216-1000 | 50-260 | 4.1 |

1200 | 12 | Y7.5-6 | 1170-1600 | 155 | 7.5 |

1500 | 16 | Y7.5-6 | 1340-2740 | 235 | 10.5 |

RXC(high weir spiral classifier)