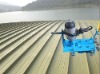

1,Raw material: Choi steel, galvanized steel sheet 2,uses for decorating house 3,wallboard structure 4,automatic operation

:

Technical process | decoiler- guiding& feeding - roll forming- cut to length-discharge-punching ends |

| Illustration | punching ends generally match 6-10 tons punching machine, and match mould 2-3 times, and then punching to finish. If the user needs this equipment, our company can customize, but Costs extra. |

| Technical parameters | Rolling speed:10-16m/min Raw material: Choi steel, galvanized steel sheet Thickness: the topping 0.4-0.5mm, the bottom 0.3mm Forming roll: 12-16 leveling rollers + edge-on roller Roller material: 45 #steel Roll surface coating hard chromium:0.05mm Main shafts:φ55mm spindle materials:45#steel Main power:3kw Reducer: Cycloidal motor reducer Drive: by gear chain Finishing cutting off: automatic hydraulic cutting off Hydraulic cutting off power: 3kw Controller: PLC auto system Host structure: wall-board type structure Host dimensions:abt. 7000*1000*1000mm |

T type keel roll forming machine MADE IN CHINA